Case Report: Printing a Perfect Smile with Dental 3D Printing

Case Study by Dr. Chonway Tram

Summary: Dr. Tram was able to print and fit an aesthetic restoration in less than three hours. The patient was ecstatic about her new dental application and the high-quality and time savings that using Ackuretta’s SOL Dental 3D printer brought to the process.

The Problem

A 23 year old female patient named Teresa* came to Dr. Chonway Tram’s clinic in Rancho Cucamonga, California with insecurities concerning her smile.

Teresa wanted to cosmetically enhance her smile before an important life event. The patient has congenitally missing maxillary lateral incisors and had orthodontics completed prior to her visit to Dr. Tram’s clinic. She was wearing a hawley retainer with lateral pontics and wanted a non-removable option. Implant treatment was discussed but, due to converging roots and a lack of bone availability, this option was discounted. Fixed partial dentures were also discussed as a future option, but both Teresa and Dr. Tram wanted minimal tooth reduction. Maryland bridges were planned to cantilever off of the maxillary centrals.

The Solution

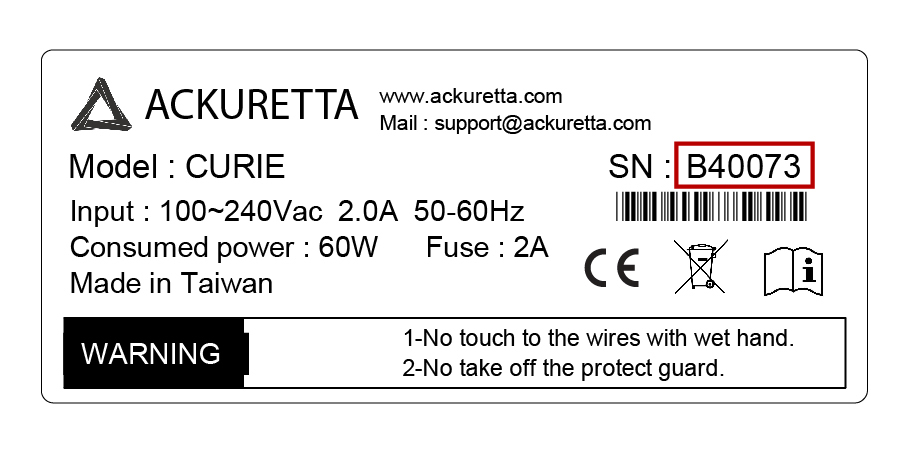

The Ackuretta SOL 3D printer was decided upon for use with Pac-Dent Rodin Sculpture resin prior to fabricating permanent Maryland bridges in lithium disilicate. The accuracy of the SOL allows for minimal tooth preparation while creating a restoration that offers a snug fit with maximum bonding area. Rodin Sculpture has the strength and bonding capacity to operate in an aesthetic function. Minimal tooth preparation was performed on the lingual aspects of the maxillary centrals, as well as gingivoplasty in the lateral area to create ovate pontic space.

Dr. Tram scanned the prep using a Medit i700, designed Maryland bridges in Exocad, and printed restorations with Ackuretta's SOL and Pac-Dent’s Rodin Sculpture A1 resin. After printing restorations were hand washed using 99% IPA, dried and cured according to IFU specifications. The restorations were then stained and glazed with the Pac-Dent Palette Naturalizing Kit and All-Purpose Glaze. The intaglio surfaces of the restorations were then sandblasted with aluminum oxide and primed & bonded using Adhese Universal and Variolink LC.

The Result

Teresa was ecstatic with the results as she had become tired of wearing a removable prosthesis. Some changes are still to be made for the final restorations such as improving the distal line angles. Dr. Tram mentioned that high wear and discoloration resistance provided comfort that these restorations will continue to look good over time. Teresa is aware that these restorations are purely aesthetic, particularly due to the size of the connectors and relative strength of the resin chosen. In cases like this it is essential to know the strengths and limitations of the material used.

From start to finish this case took approximately two hours to complete. Using Ackuretta’s SOL 3D Printer with Rodin Sculpture allowed multiple restorations to be printed at once and completed on the same day. The versatility of the Rodin Sculpture resin in combination with the reliability of the SOL make Ackuretta’s 3D Printer a must have for any dental practitioner considering dental 3D printing.

The Magic of 3D Printing

Dental 3D Printing enabled Dr. Tram to complete this treatment over one day and one appointment, saving time for both his practice and for Teresa. Thanks to the precision and accuracy of Ackuretta’s SOL 3D Printer, both patient and provider have access to a high-quality solution that promises long-term biocompatibility and comfort.

Digital dentistry is slowly changing the dental industry day-by-day. With solutions like the SOL which are easy to use, come with leading customer support, and bring immediate productivity increases it is no surprise that more practitioners are choosing 3D printing for dentistry.

___________________________

* The patient’s name has been changed for privacy purposes.

Chonway D. Tram, DDS, FICOI

Born and raised in southern California, I graduated from Loma Linda University, School of Dentistry in 2007. I continued my education in New York City at St. Barnabas Hospital, where I completed my GPR. With a sound surgical and restorative base I moved back to California and associated before I opened my office Kaio Dental, in Rancho Cucamonga in 2013. Digital dentistry has always been a part of my office, specifically CAD/CAM. The convenience of same day crowns appealed to my patient population, and I loved the chairside aspect of design and shade customization. That lead to me to the possibilities of 3D printing in 2017. It started with FDM printers just creating surgical guides, and that followed with resin printers making wax-ups and aligners. Today 3D printing is a major aspect of my office creating restorations, removable and hybrid prosthesis’ and splints along with the previously mentioned.

To be able to control many aspects of patient treatment is an amazing benefit of digital dentistry and 3D printing. As resin technology advances, the material choices will be more resilient and provide practitioners the ability to to provide patients with better, faster care. 3D printing has a bright future in dentistry. By no means will it replace the traditional lab, if anything digital dentistry as a whole will interconnect the lab and the office in a more efficient fashion. For those looking to get into 3D printing, the best time to start is now! Dentall 3d printers today have a lower cost of entry than CAM machines, and with its variable functions and low material cost, positive ROI is easy and fast to achieve. 3D printing is a paradigm shift in dentistry, and it will only elevate our level of care to patients.

Loading ...

Loading ...