Why nitrogen is essential for your Dental 3D Printing curing station

The popularity of 3D printing in the dental industry has been expanding, and along with it the technology itself and the quality of output it is capable of producing. Today a dentist or lab technician can create a print faster, more easily, and more accurately than ever before. These improvements have led to an increasing number of dental professionals seeking the latest developments to add to their arsenal of tools – including the most advanced UV curing ovens and nitrogen sources.

Having all the right elements working together – from design to delivery – is the key to getting consistent results every time. A fully synchronized UV curing station is the final step to guarantee high quality, precise, and accurate results.

What is Dental 3D Printing?

Dental 3D printing is a digital dentistry process that involves producing a final dental application – a crown, model, surgical guide, etc. – via a digital workflow, with the application created from liquid resin through a process of polymerization.

The dental 3D printing workflow includes the initial intraoral scanning and digital design, followed by the printing itself and, perhaps most importantly, post curing steps. The final application is made from liquid resin which, through a process of polymerization, creates a solid print. UV light curing – especially the final cure after printing – is what ensures the quality and biocompatibility of a print; it is where the majority of curing happens. UV lights at specific wavelengths ensure the optimal strength, biocompatibility and aesthetic of the print. Incorporating nitrogen into post curing to enhance this final result seamlessly augments the dental 3D printing workflow.

Compared to a traditional analog workflow, 3D printing speeds up the process for the patient and the dental professional. The addition of nitrogen when curing 3D prints brings additional improvements to the accuracy and quality of your final result.

What Are the Benefits of Post Curing with Nitrogen?

Post curing with nitrogen using UV light solidifies the final print, and ensures it has met a set of health standards which reaffirm that it is safe to place in a patient’s mouth. This is especially important for restorative treatments and Class II applications.

Enhanced Mechanical Properties

Incorporating nitrogen increases the quality of prints by enhancing their mechanical properties, including up to 25% higher flexural strength. The cross-linking that is achieved through post curing is improved, leading to a stronger and more durable result. Furthermore, incorporating nitrogen into the post curing process ensures more consistent results. This means that patients are reliably receiving a better and more comfortable solution, and practitioners can deliver the best results possible each and every time.

Better aesthetics for dental applications

In addition to improved comfort and durability, nitrogen integration yields a higher-quality print with fewer sticky areas and cracks. It also creates enhanced aesthetics for transparent resins and avoids the distorted appearance that often appears after post curing. Nitrogen integration improves the color and smoothness of the final result, providing a more natural look and feel for applications that will be placed in a patient’s mouth on a more permanent basis. This in turn leads to better patient satisfaction, and the potential for more referrals or practice expansion.

Consistent UV Curing for resin 3D printing

Nitrogen maximizes the consistency of the 3D printed application and ensures that the print is cured evenly. This increased consistency helps reduce material waste. A curing method that is pre-tested and validated reduces trial-and-error, mistakes and re-prints, leading to the maximized use of all your material investments.

Maximized Efficiency for dental workflows

With the oxygen inhibition effect negated, curing happens faster and more evenly, reducing curing time and giving the patient a high quality result.

Today, patients are better educated on the treatment options available to them, and the technologies that are emerging. They are more interested and involved in their treatment, and want the best quality and the best price on the market. They also want the least number of visits possible, and will seek dentists with established expertise, knowledge, and technology offerings. When it comes to oral health, 3D printing is increasingly being sought by patients and oral healthcare providers due to the benefits it offers that a traditional workflow cannot, with nitrogen increasing the benefits of UV curing further.

The Science of Curing with Nitrogen

Post printing UV light curing is a continuation of the polymerization that takes place during the printing process. The print is placed inside a UV curing chamber, where it is then hit with UV light of specific wavelengths at all angles. This process ensures that the print is fully cured from all directions, and safe for the patient. While a print may look solid from the outside, it is possible that some uncured resin remains inside. Uncured resin can be toxic and harmful to a patient, which is why UV curing is essential.

When the print is placed in the curing chamber, oxygen is also present inside. This can be problematic due to oxygen’s inhibiting effect on for a UV reaction, which reduces curing performance by preventing UV rays from fully penetrating inside the print and curing it completely. In addition, oxygen can create light distortions, causing certain areas to cure unevenly.

When nitrogen is introduced into the chamber, it displaces the oxygen, thereby creating an inert oxygen-free environment, where the UV light is able to cure the print without any inhibiting effect – there are no layers between the UV light and the print, which means there is more efficient light absorption. It also prevents contamination from dust or other particles which might be present in the chamber, as well as oxidation and discolouration. By substituting air with 95% pure nitrogen, many improvements and enhancements to the final output become possible.

How does a Nitrogen (N2) Generator extract nitrogen from the air?

There are several different ways to extract nitrogen from the environment. Two of the most common ways to do this are:

- Pressure swing adsorption (PSA)

- Membrane nitrogen generation

In the digital dental realm, the most common way to extract nitrogen from the environment is pressure swing adsorption. PSA has the potential to deliver top-quality results by creating extremely high nitrogen purity (up to 99.9995%), while being extremely reliable and having a long lifespan, making it a solid investment for a practice.

PSA works by separating the nitrogen molecules from the oxygen molecules that are present in the compressed air being fed into the generator. Each generator has two towers or adsorber vessels, which contain carbon molecular sieve designed to adsorb the oxygen molecules. While one tower is going through a process of adsorption (also known as separation or pressurization), the other is going through desorption (a.k.a. regeneration or depressurization). Both towers work simultaneously performing opposite functions, and alternate in a cyclical way, thus achieving a constant flow of nitrogen.

Image source: Peak Scientific

Image source: Atlas Copco

Another way for a nitrogen generator to extract nitrogen from the air is through membrane nitrogen generation. This method involves forcing compressed air to flow through hollow fiber membranes. These membranes allow the nitrogen molecules to pass through more easily than other gasses such as oxygen. They are semi-permeable, and allow for easier permeation of oxygen and other gasses, while the nitrogen gets pushed through and collected on the other side. Additional processing is done after that to remove any remaining gasses or other impurities. The final result is high-purity nitrogen gas.

Image source: Atlas Copco "Comparing Pressure swing adsorption and membrane nitrogen generation"

Nitrogen Generator and Nitrogen Tanks

There are two methods to integrate nitrogen into compatible UV curing units and dental 3D printing workflows: using a nitrogen generator, or nitrogen tanks.

Nitrogen tanks are the more traditional option. They are an accessible, cost-efficient method with an intuitive installation process. A wide variety of different types and sizes of manufactured tanks can be used in the UV curing process. One aspect that users should be aware of is that tanks need to be replaced after 35 curing cycles to ensure the inert environment that contains minimal oxygen.

Nitrogen generators offer an unlimited supply of nitrogen eliminating the need for refills and reducing material waste from the disposal of used tanks. Once a generator is installed there is minimal maintenance required, which can be more convenient for some practices. Generators are on average smaller than a nitrogen tank, taking up less space in a practice.

With pre-set settings in nitrogen generators, users don’t have to worry about potentially inconsistent results or malfunctions that could result in a loss of time and material resources.

A significant benefit for some nitrogen generators is that they are built and validated for a specific dental 3D printing workflow, which will lead to higher quality dental applications, less trial and error, cost savings, and productivity enhancements.

Overall, both tools can be a positive addition to your dental 3D printing workflow.

Nitrogen vs. Vacuum vs. Glycerin: Which Method is best for curing resin?

While the use of nitrogen as a tool to prevent oxygen inhibition during the curing of a print is the most common, other methods also exist to eliminate oxygen’s negative effects on the final print result.

Vacuum Purging

Vacuum purging refers to the removal of oxygen from the resin before it begins printing. This process ensures that once the resin is removed from the vacuum environment, the bubbles will be removed, and the final print will have no inconsistencies or flaws as a result of bubbles being trapped in the resin.

While this can be good to improve the quality of the print and reduce failure rates, it can be very time consuming, expensive to integrate, and result in material waste.

Glycerin or other liquids

Another way to prevent oxygen from negatively affecting your print is to place the print into a liquid before curing, or to coat the print with a thin layer of glycerin before placing it in the uv light curing oven. Once it is in the inert environment, oxygen can no longer affect how the light accesses and penetrates the print, thus eliminating the issues oxygen can cause during UV light curing. By placing the print in a liquid which then gets placed inside the curing unit, the light will be unhindered, and thus allow the print to cure evenly.

But while this can work for certain applications, not all resins are compatible with this method, and placing them in a liquid for the purpose of improved curing can be problematic.

Despite the many options available to improve a 3D printed application and reduce the negative effects of oxygen, nitrogen is commonly seen as the optimal solution. When evaluating application quality and convenience, it is the leading method that can be employed for improving prints, enhancing mechanical properties, and delivering the best results to your patients.

What You Need in a UV Curing Station in 2023 and Why You Want To Add Nitrogen

Today, the dental 3D printing market is trending toward permanent materials and 3D printed restorations that need to achieve optimal mechanical properties such as flexural strength, hardness, surface roughness, and wear resistance. There is an increasing demand for nitrogen-compatible UV curing units which can merge seamlessly with a clinic or lab’s current workflow. Curing units with nitrogen integration are providing dental professionals with the best results for their customers, with long-lasting features.

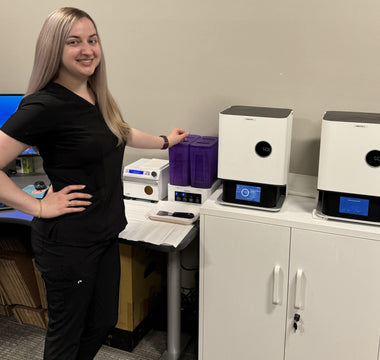

In 2023, dental practitioners including labs and clinics are looking for a complete end-to-end solution that incorporates a full workflow – where each device is integrated, streamlined, and fully compatible. Ackuretta’s 3D Printing Solution offers this – with its ALPHA AI slicing software, the SOL and DENTIQ 3D printers, the CLEANI washing station, and the recently released CURIE Plus UV Oven. This complete workflow allows users to maximize their output while minimizing costs, training, and time spent on trial-and-error.

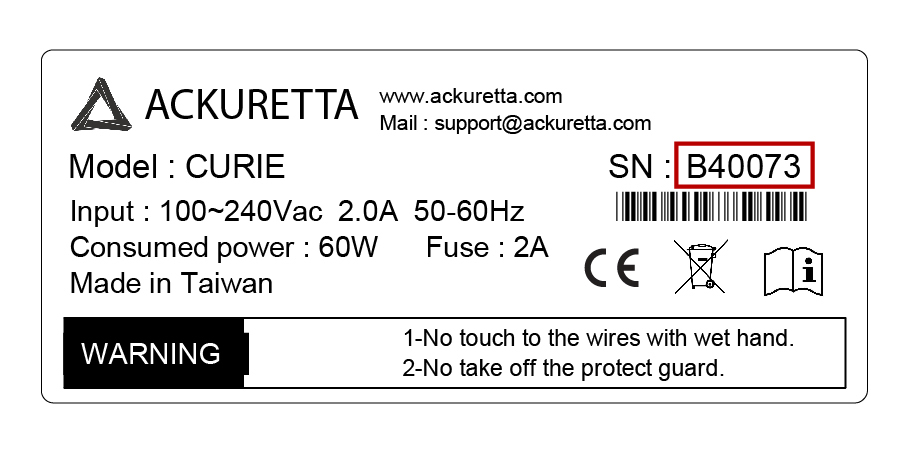

Ackuretta’s newest UV Curing Oven CURIE Plus provides a pre-loaded set of curing parameters to make it even easier for users to achieve safe and biocompatible outputs. CURIE Plus is specifically designed to work with nitrogen sources - capable of integrating a nitrogen flow directly into the UV curing chamber.

Learn more on Ackuretta’s website, or contact Ackuretta’s Customer Success Team for more information on how dental practitioners can elevate curing to the next level.

Loading ...

Loading ...